Gudmund strengthens our team!

Gudmund strengthens our team! Gudmund, who started with us at New Year’s, has his background from

Gudmund strengthens our team! Gudmund, who started with us at New Year’s, has his background from

Uplifting season! A lot has happened during the winter. We have received several orders from both

Mads is back! Mads Hauge is back after checking the world outside Ecco it. He knows

Deep diving into automation to unearth hidden treasures Arild Bergesen Husebø has found the driving force

Our solution for condition-based maintenance is taking form After a long development process, a complete gen-1

Morten will contribute transform our oil & gas solutions to other industries Morten Sædberg recently had

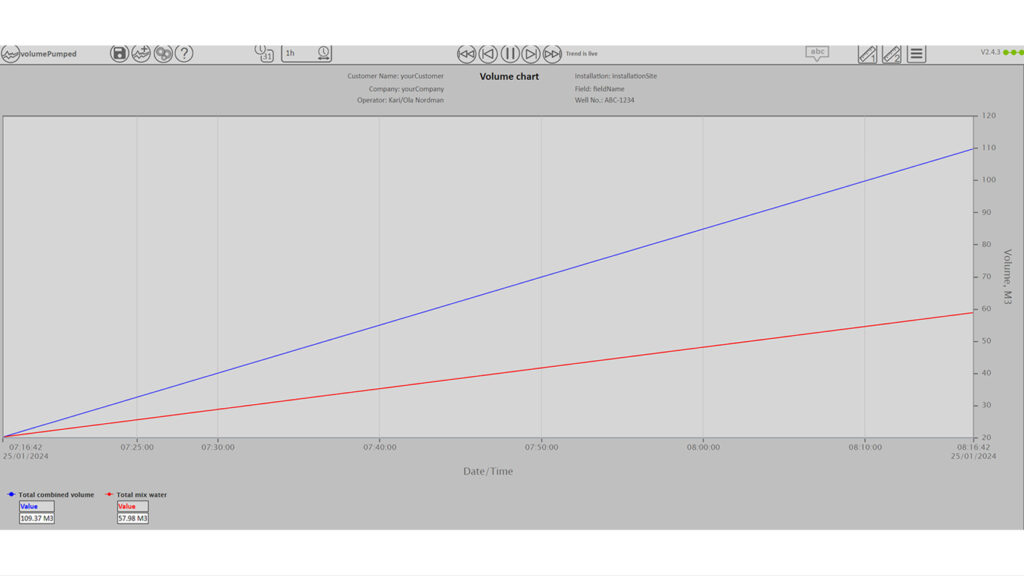

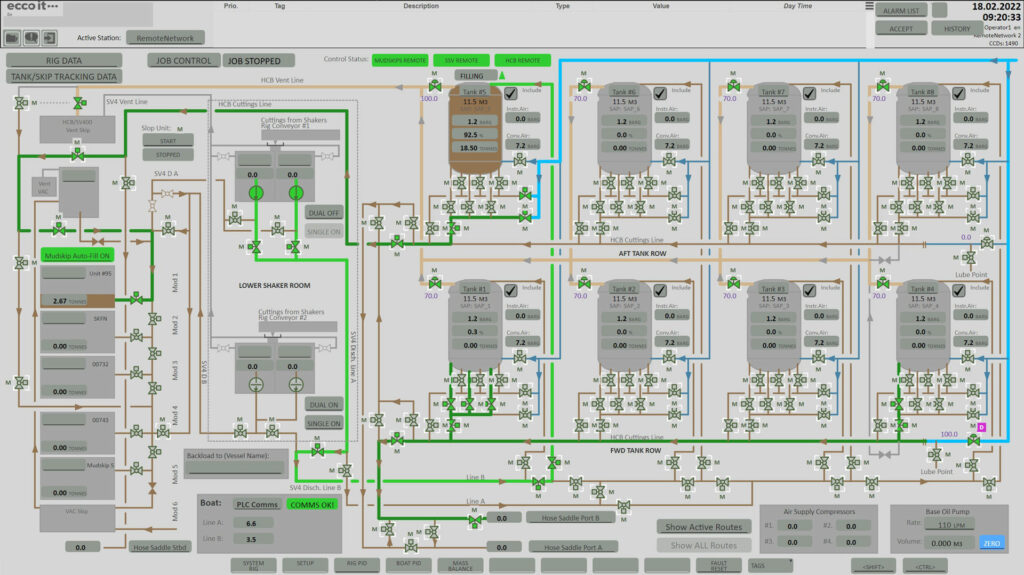

A long-planned expansion of our remote control system for drill cuttings management (DCM) has finally been installed and tested

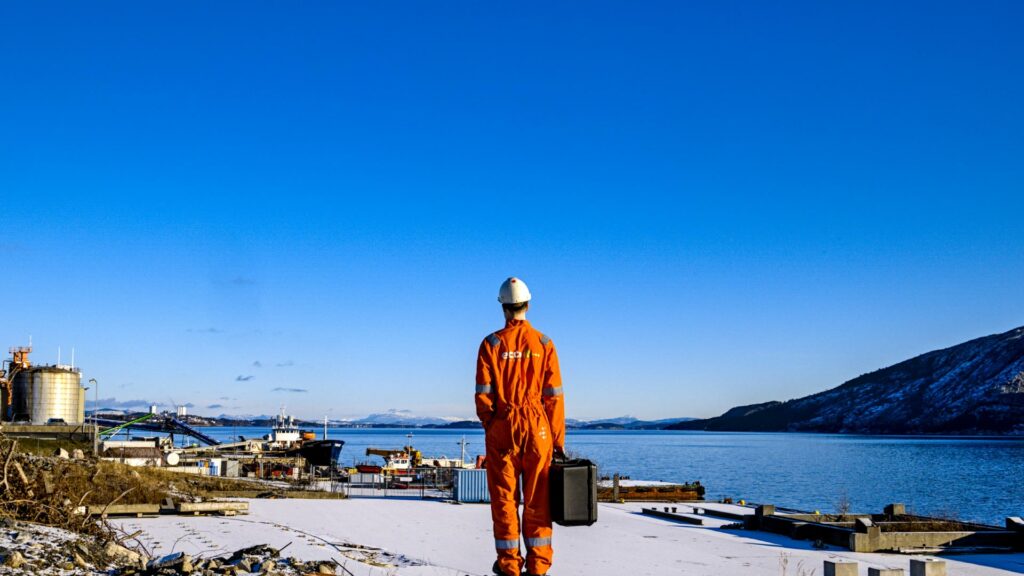

This small box can cut your installation cost and emissions by 50%

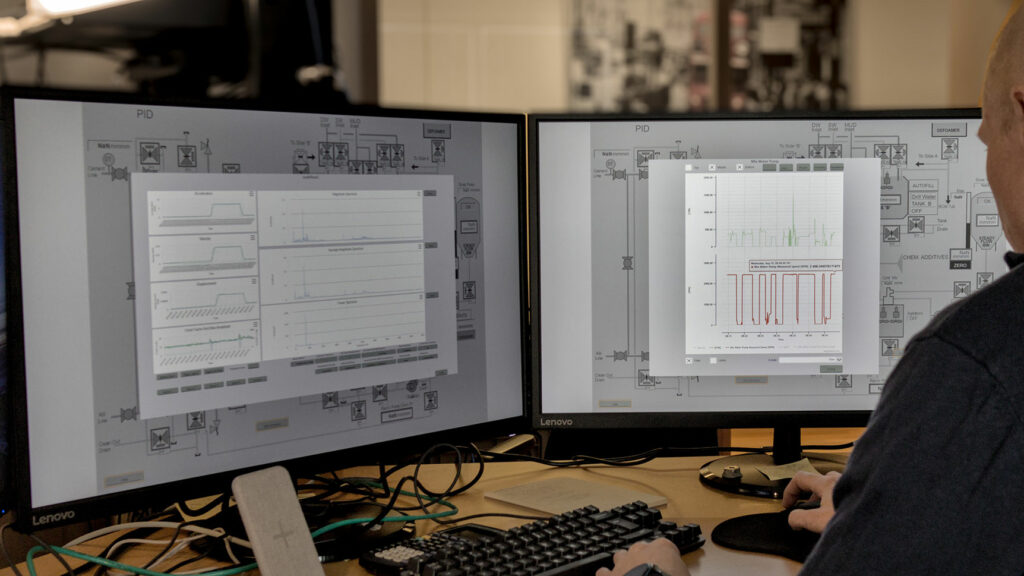

Some of our brightest heads have spent the last months implementing a secure online connection to a fixed installation in the North Sea.

The autumn has been very hectic with several large and some smaller projects both in Norway and in the east. We seem to be on track.

Recently a new remote-control system for process operation has been tested and prepared for delivery. Over the coming fall, our system will be installed on a fixed offshore installation in the North Sea.

New substantial order received for delivery of a remote-control system for drill cuttings mangement

Reduced need for onsite personnel leads to improved working conditions and HSE, reduced costs and emissions, and an overall efficiency gain.

Collectively, these facilitate support, reporting, monitoring, and operation, all fully remotely.

Two control systems have been installed on the other side of the planet by local labor and commissioned with zero added CO2 emissions, and at significantly reduced cost.

Operations are now moving from manually handled line-ups and VHF radio communication to having full overview on activities in the control room.