Confident decisions start with clear data. With our deep expertise in sensors, automation and IT, you’ll gain the insight needed to reduce costs, boost quality and lower risk. Our open, scalable technologies ensure your systems evolve with your business – sustainably and seamlessly.

Our steps in automation ends with a handover to IT

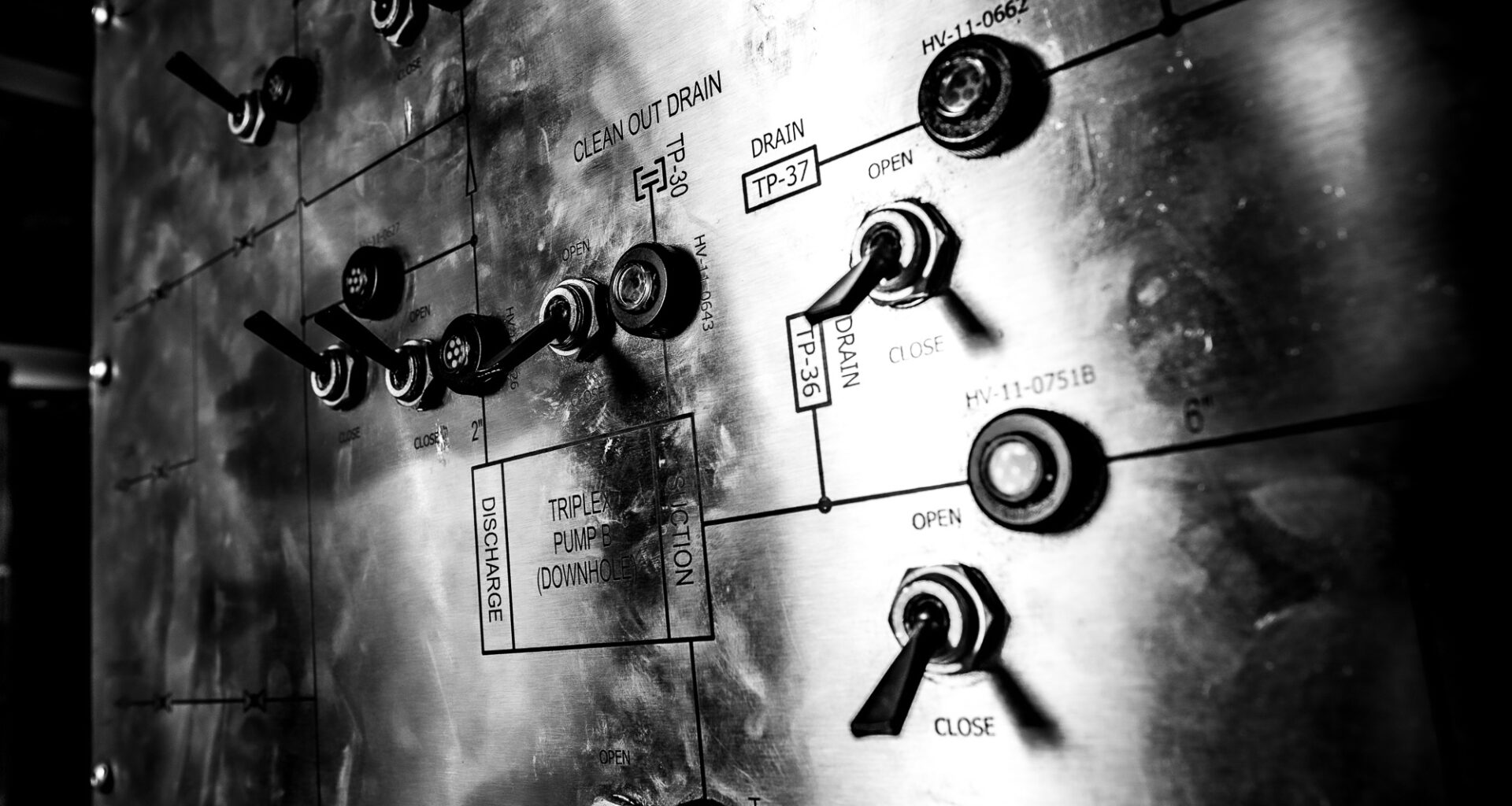

control it

Equip your process plant with sensors, PLCs, and servers, plus remote control software to build a solid base for future digitalization

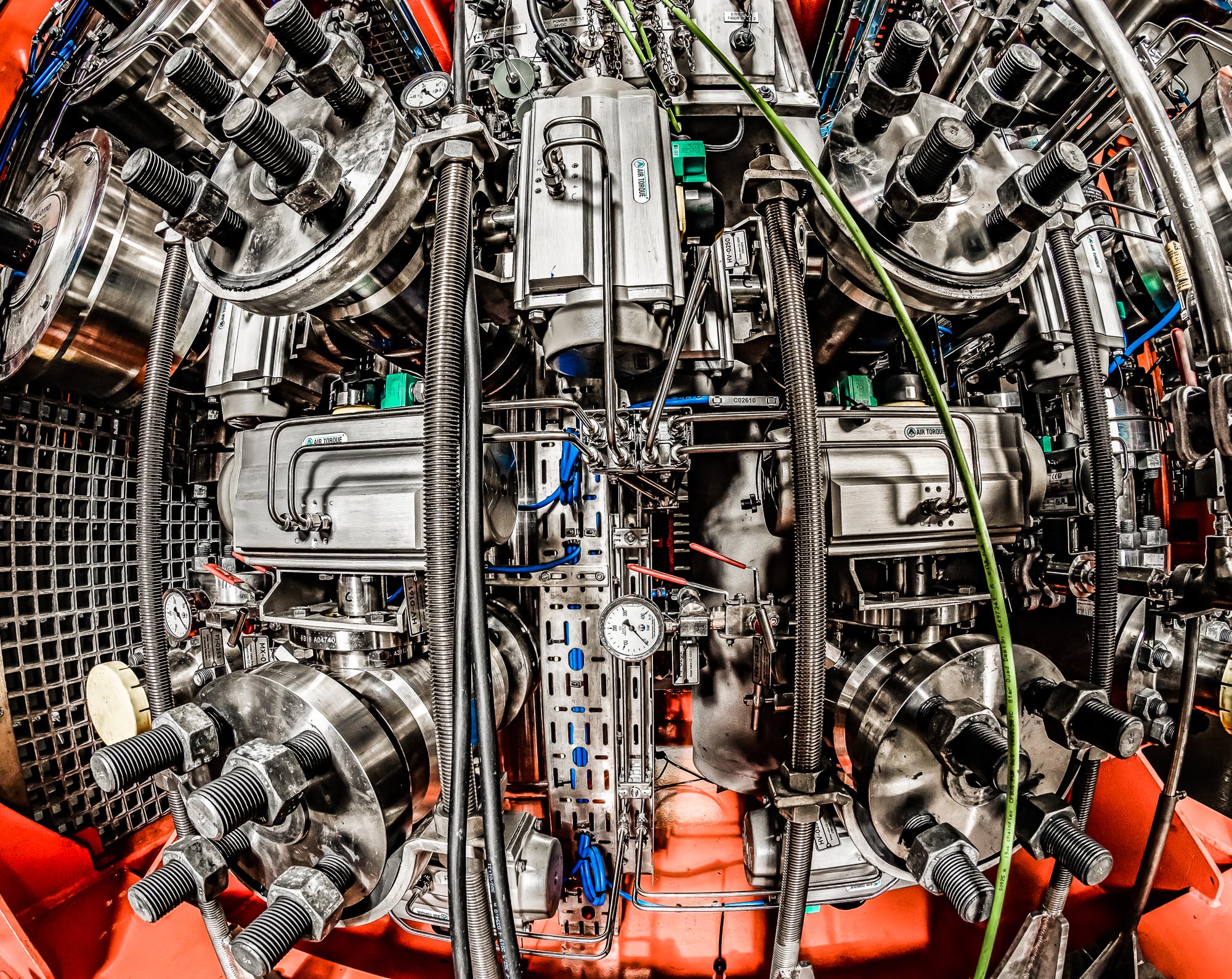

integrate it

Unify processes and machines under one control system to optimize resources. The OPC UA communication technology enables standardized data exchange and seamless integration.

robotize it

Automated sequences ensure quality, efficiency, and safety allowing operators to supervise while robots follow best practices. Consistently!

report it

Real-time and historical data are fully integrated into the control system, accessible from anywhere. Playback functionality lets you review exactly what happened.

support it

Troubleshooting assistance and guidance via online access when needed, and software updates when appropriate. Less waiting, less hassle, less downtime!

predict it

Monitor equipment and process parameters to boost efficiency and shift from scheduled to condition-based maintenance. Take action when it matters!

simulate it

Train and test on a digital twin to simulate operational changes, onboard new operators, and engage end users. All in a safe, virtual environment.

know it

To achieve optimal production, you need seamless OT–IT integration. This makes success scalable and enables ML and AI for continuous improvement.

When OT meets IT, your production becomes smarter, cleaner and ready to grow. Unlock streamlined operations, sharper decisions and scalable success – all built for the future.

We prepare you for the future!