FUTURE-PROOF INDUSTRIAL AUTOMATION

Sustainable activity by reducing human presence, increase quality and reduce risk with control systems for remote operations and monitoring of processes and machinery.

Integrate existing equipment with new and transform it all into a robot that performs according to best practice – always!

All software from Eccoit is based on standardized and open technologies.

At the end of the day, it’s all about resources!

Our scope of supply

Complete software package for full control

and all information from anywhere

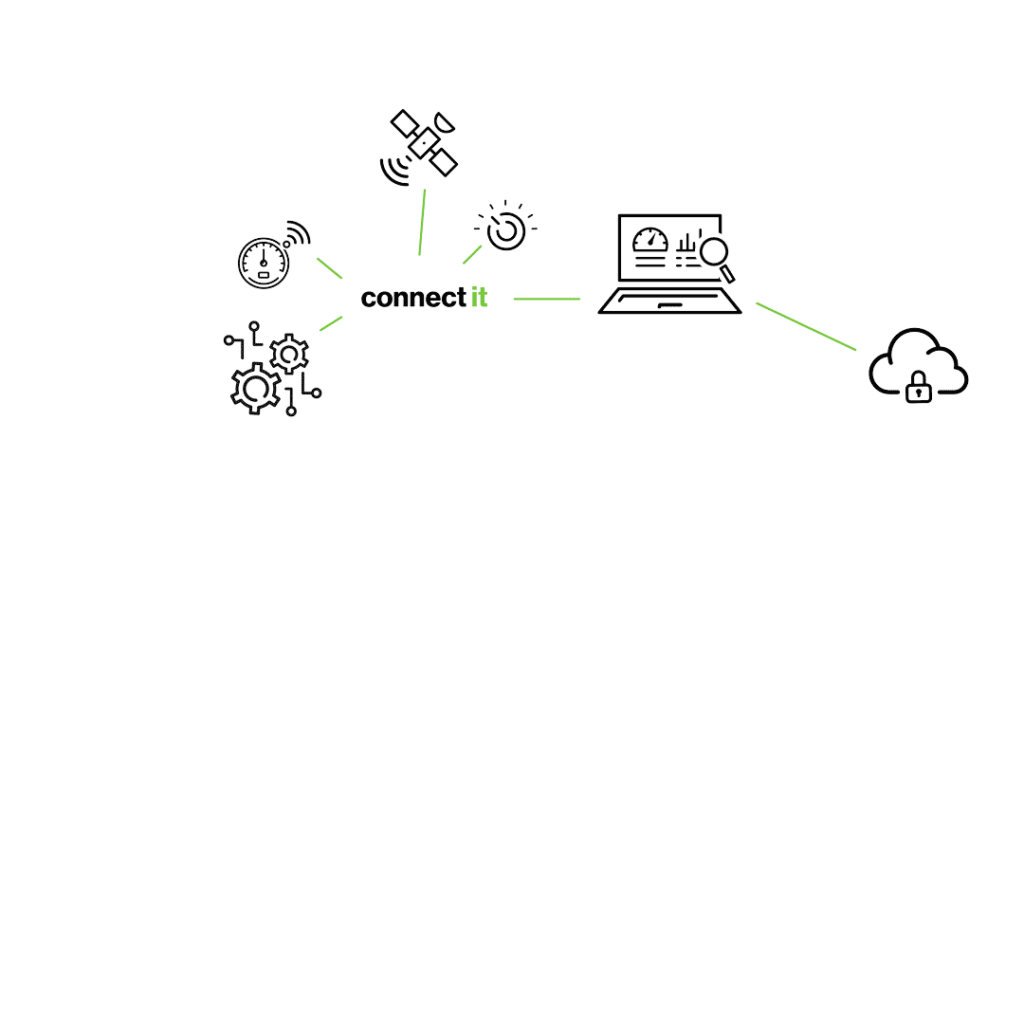

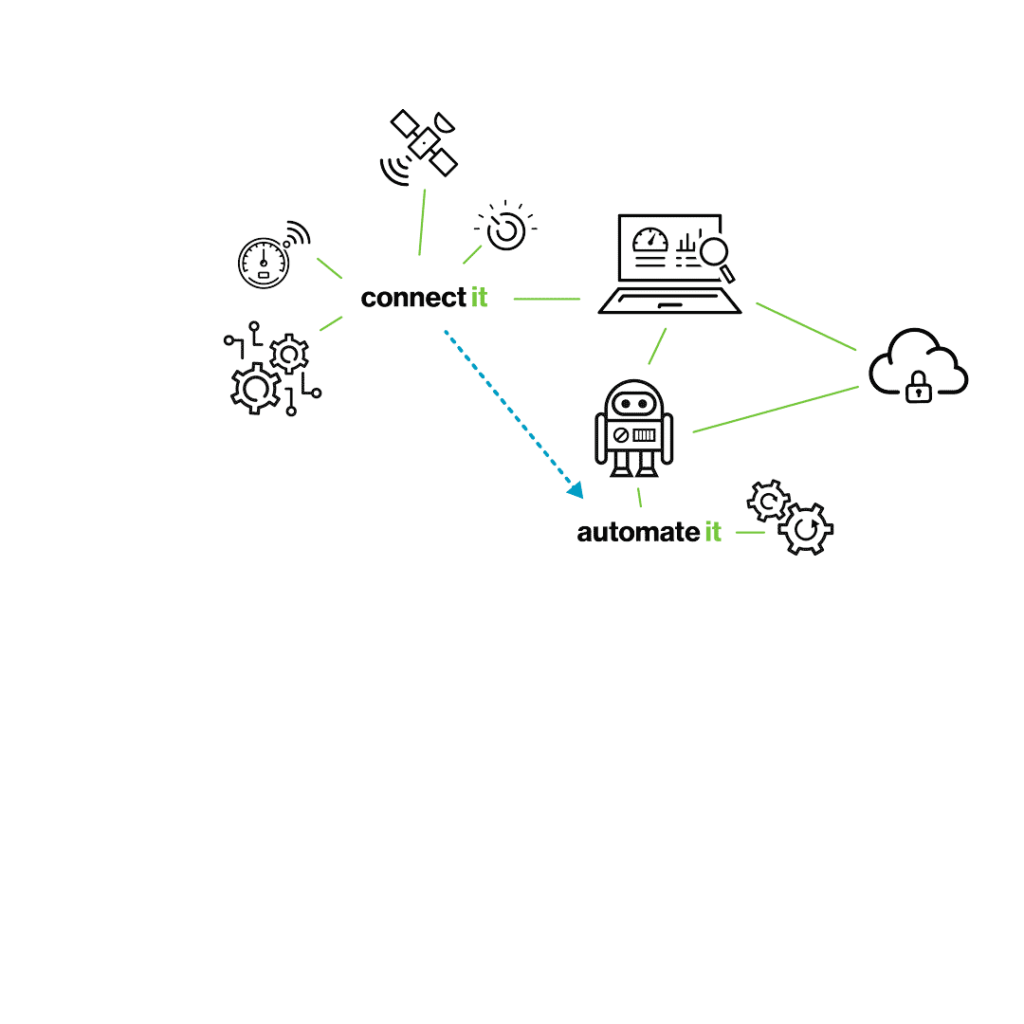

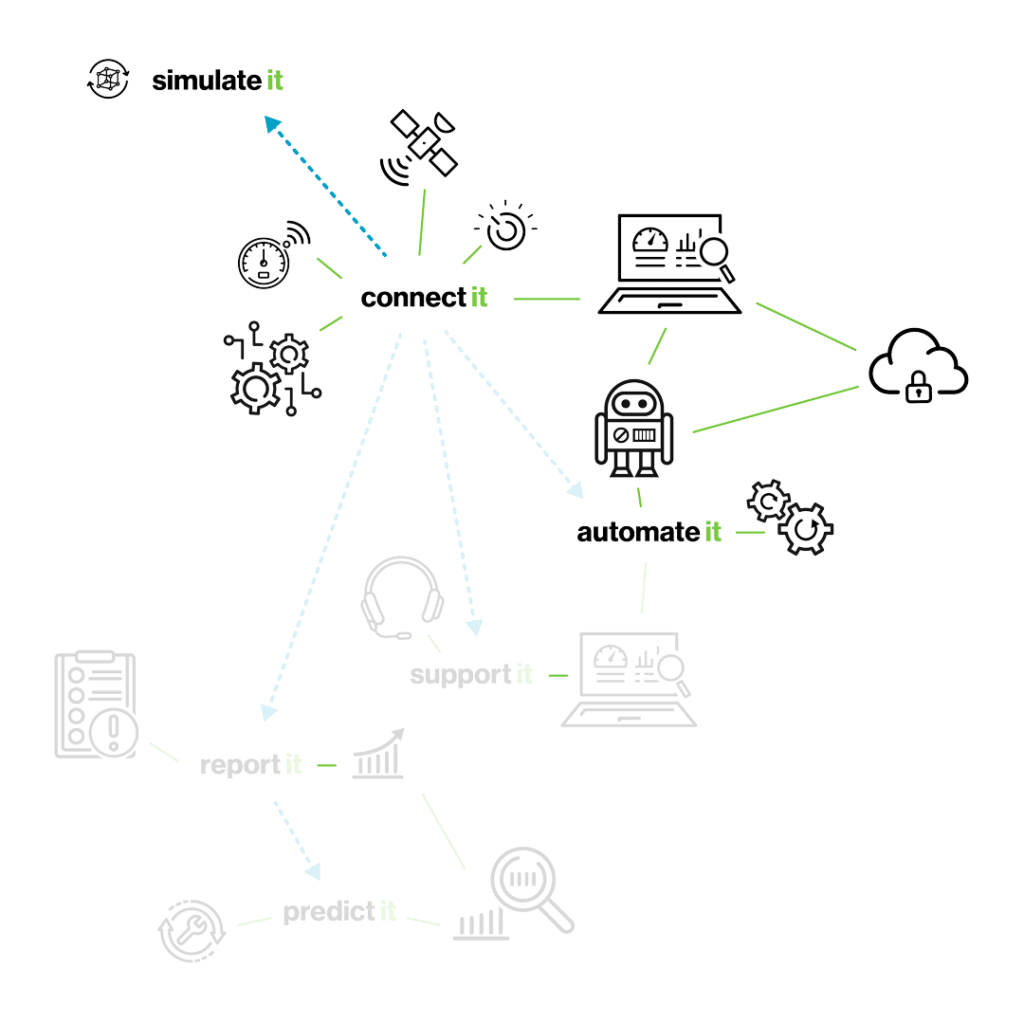

We are building software modules that cover everything you would expect from a control system for process plants – both today and in the future. These all build upon our Connect it framework that facilitates control and monitoring via the internet using standardized and open technologies.

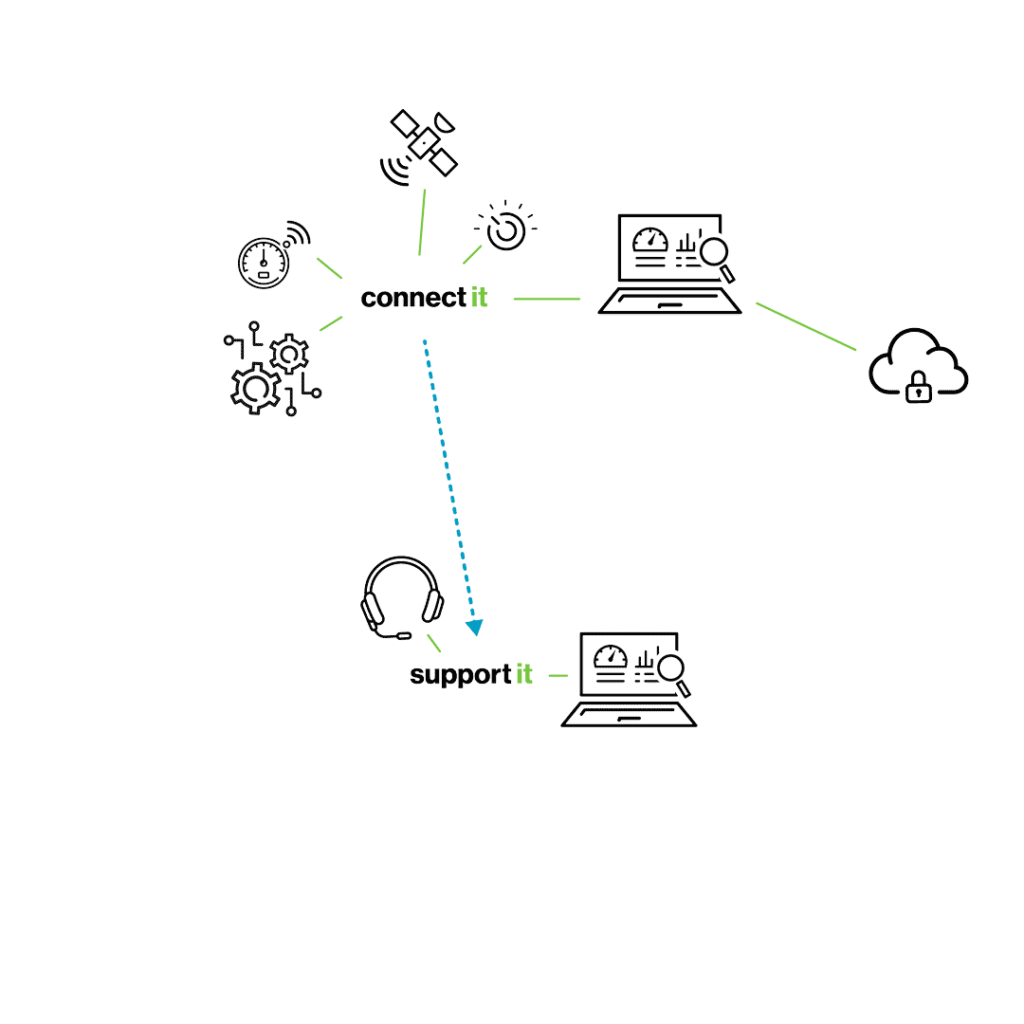

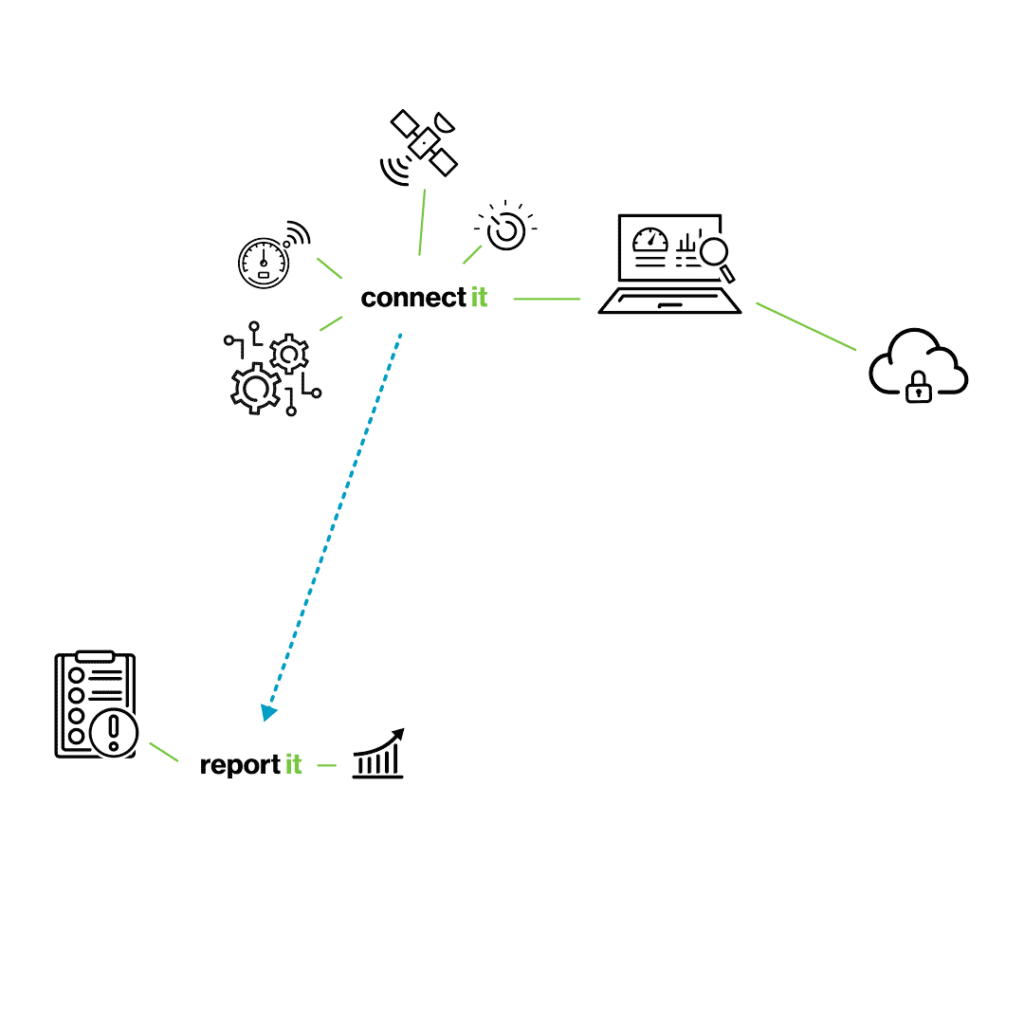

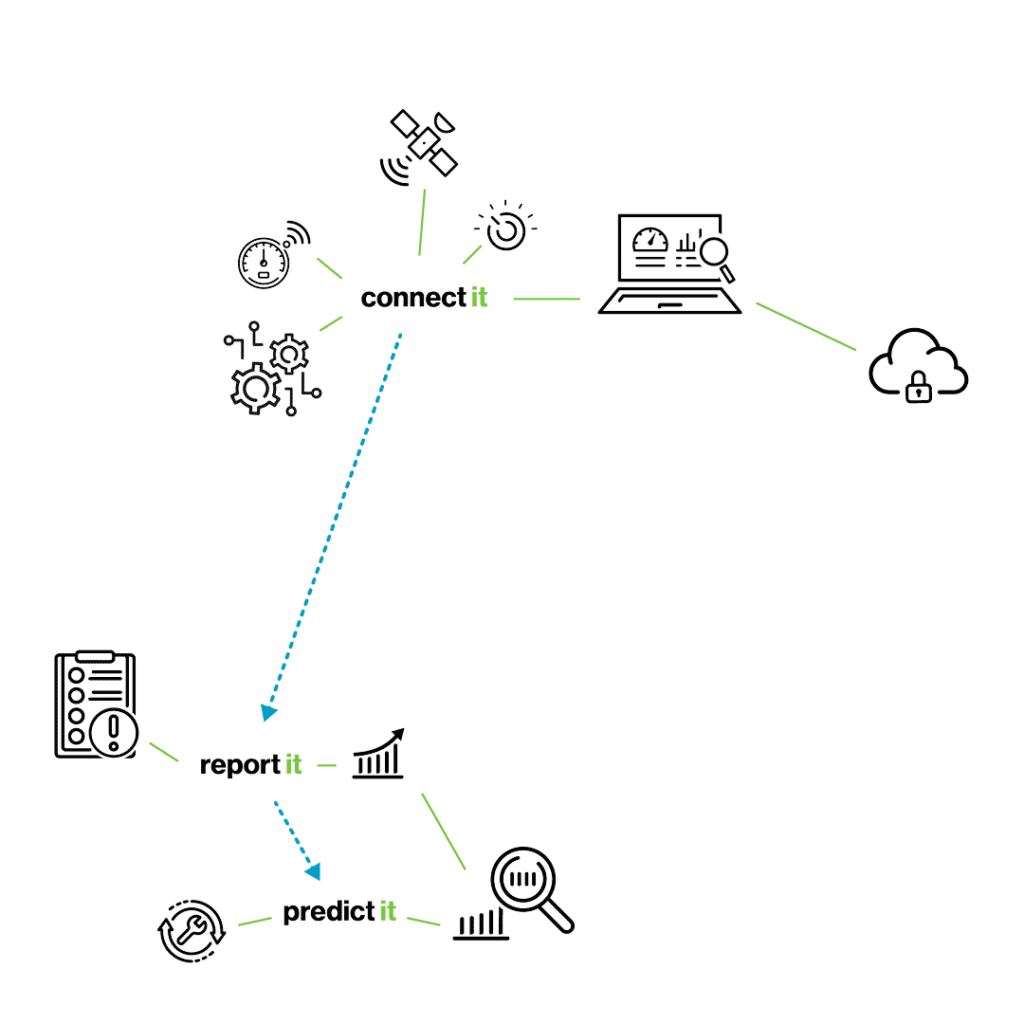

connect it

Get connected

Lay the foundations for remote control. Connect hardware and software, and bring your system online.

automate it

Robots do not make mistakes

Boost quality, efficiency, and safety with automated sequences to manage the details of the process. The operator keeps their overview, while the robot is there to assist.

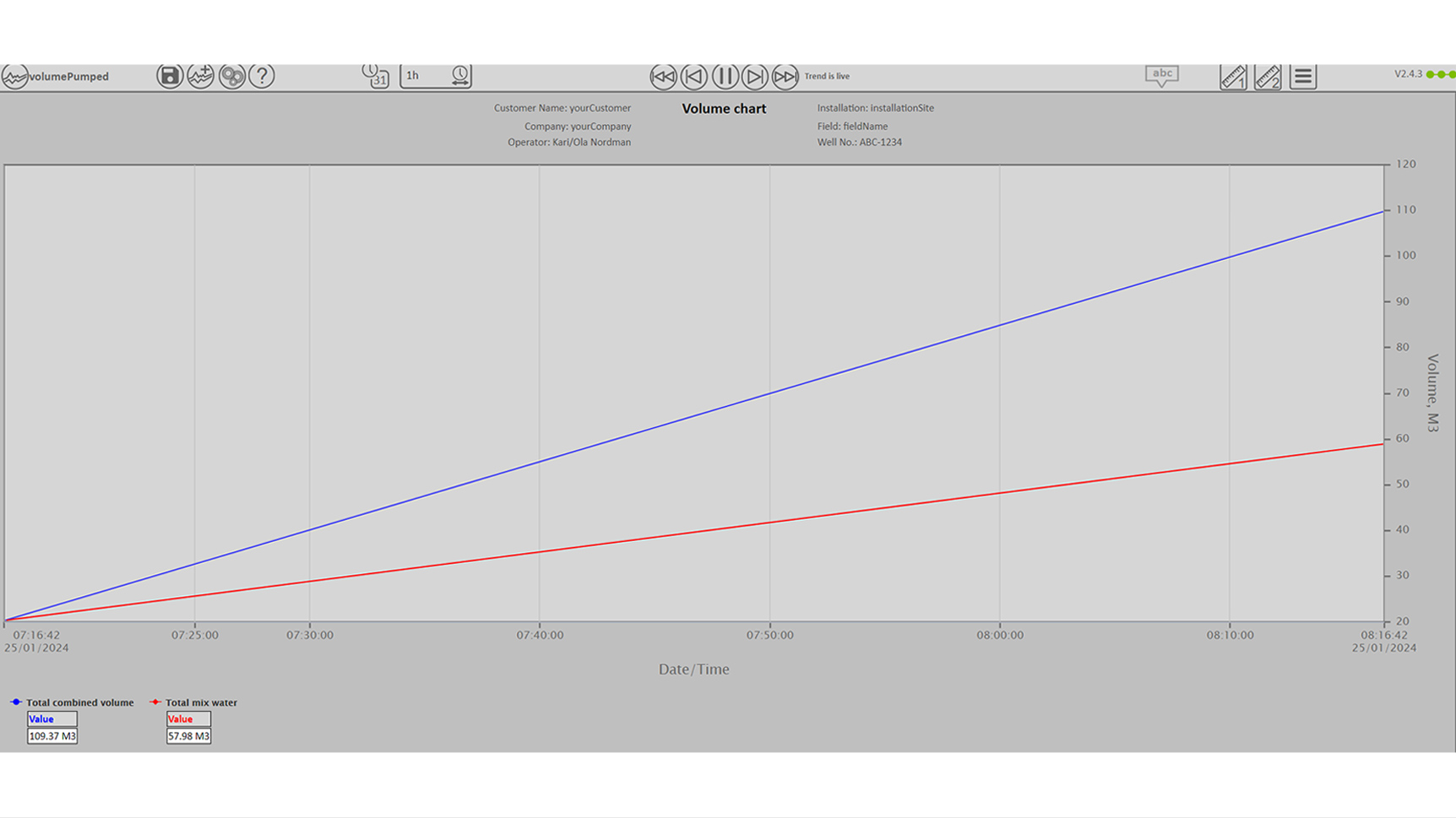

report it

See all, know all

Live trends and historical data, directly integrated into the control system and accessible from anywhere.

support it

Stay connected

Receive live support and troubleshooting when needed, and software updates when available. Less waiting, less trouble, less downtime.

predict it

Two steps ahead

Monitor equipment conditions and process parameters to improve efficiencies and reschedule maintenance to when it is actually needed.

simulate it

Try this on for size

Test and train on a digital twin of the plant to simulate operational changes, prepare new operators, and to link the end-user into the design loop.

the gains

Save costs and

resources

Taking advantage of internet access to achieve remote presence provides a significant reduction in cost and resource consumption.

INCREASE QUALITY

& REDUCE RISK

Our automated systems perform each operation with the same quality and in accordance with best practice, reducing operational risk by quickly reacting to problems in a predictable manner.

REDUCE THE CLIMATE

IMPACT

Increasing the level of automation and ‘smart’ operations in your industry will make a significant push towards minimizing its environmental footprint.

INTEGRATION RELEASES

RESOURCES

Growing process facilities often face an increasingly tangled assortment of control and monitoring systems. Our solutions can integrate these, improving coordination between subsystems and allowing one team of operators to handle the plant from one control station.

WORK WITH WHAT

YOU HAVE AND FUTUREPROOF

YOUR PROCESS

If requested, we can even integrate older ‘outdated’ equipment into our new systems, decreasing the cost of upgrades. By basing your facility on open standards, vendor lock-in is a problem of the past, making the system ready to tackle any future modifications where the need arises. All our solutions are non-proprietary to facilitate effective integration and scalability.

UTILIZE DATA TO

INCREASE EFFICIENCY

Analyzing process data to facilitate preventative maintenance and continual improvements can highlighting inefficiencies in the plant and how to improve them. The control system collects a wealth of data made available for analysis, and our data logging & trending solution uses standardized and open technologies for data exchange.

World’s first downhole job fully automated

and performed from shore.

We are very proud to be playing a part in this achievement"

Customers reviews